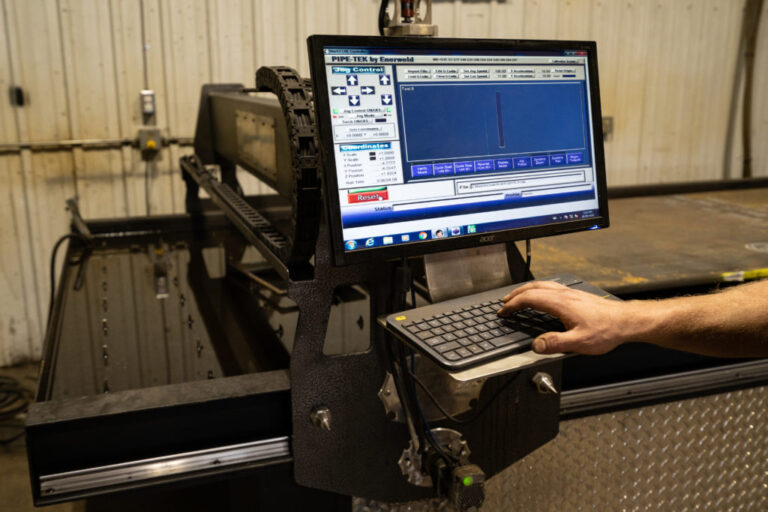

Strait’s manufacturing process includes the use of three custom built computer numerical control (CNC) cutting and profiling machines. These machines accelerate cut speed and increase accuracy and output quality. Structural steel components, piping and steel plate can be cut to our client’s specification with exact precision.

The benefits of optimized production and higher quality cuts is passed on to our customer.

This state-of-the-art beam profiling machine cuts all types of structural steel to length quickly and accurately. Increased efficiencies are realized with the use of automated infeed and outfeed, through precision marking and cut out performance, and by virtually eliminating the need for grinding.

Technical Safety British Columbia

Alberta Boilers Safety Association

Stay safe with a strong Project Partner. STRAIT brings a superior safety record and project delivery approach to every project.